Leading Asphalt Drum Mix Plant Manufacturer, Exporter | Road Construction Machinery

Vinayak Equipments has been a highly renowned company in the manufacturing of road construction equipment. We are a Gujarat-based company that designs, manufactures, and supplies Asphalt Drum Mix Plants, Mobile Asphalt Plants, Hot Mix Asphalt Plants, and Concrete Batching Plants, which are consistent in their performance, reliability and cost-effectiveness.

As we are one of the largest Asphalt Drum Mix Plant manufacturers and exporters worldwide, our clients are located in more than 35 countries: Nigeria, the UAE, Bangladesh, Ecuador, the Maldives, and more. Our high level of technology and our stringent quality standards will ensure that every machine with the name Vinayak will perform, work efficiently, and reliably over and above expectations.

Who We Are ![]()

Vinayak Equipment is an Indian based manufacturer and exporter of asphalt drum mix plants, high-quality and reliable asphalt and concrete plants that are manufactured according to global standards.

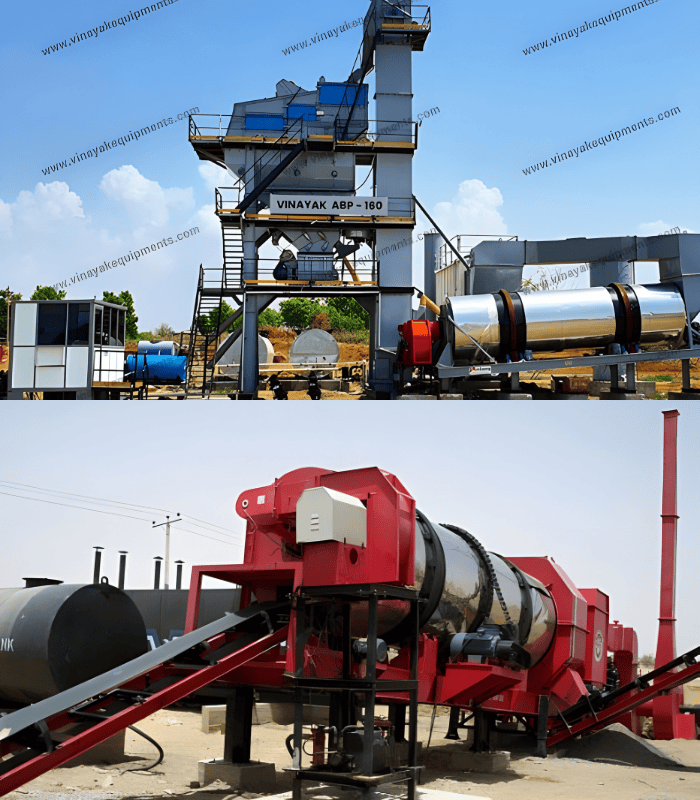

Types of Asphalt Drum Plant ![]()

One Of The Fastest Manufacturers & Suppliers of Asphalt Drum Mix Plants in India

Asphalt Drum Mix Plant

Engineered for continuous, high-quality asphalt production ensuring uniformity and durability.

Know MoreMobile Asphalt Drum Mix Plant

Fully mobile and efficient system ideal for fast setup and site-to-site flexibility.

Know MoreMini Asphalt Drum Mix Plant

Compact yet powerful mini plant — perfect for small and medium-sized projects.

Know MorePortable Asphalt Drum Mix Plant

Compact and easily transportable solution for high-performance asphalt production anywhere.

Know MoreAsphalt Batch Mix Plant

Batch-based precision control system for consistent and quality-driven asphalt production.

Know MoreWet Mix Macadam Plant (WMM Plant)

Produces graded, moisture-controlled mix for strong, durable road base layers.

Know MoreVinayak Equipments, as a manufacturers of Asphalt Drum Mix Plant with experience, focuses on precision engineering, durability, and performance. All the plants are manufactured to very high quality control standards to ensure that it performs satisfactorily in tough working conditions.

Manufacturing Strengths:

- Durability of structure and wear-resistant parts.

- A drying and mixing drum that is energy efficient.

- Sophisticated burner to ensure even heating.

- Full automation of PLC/control panel.

- Adherence to environmental standards.

Our plants can have a capacity of 20 TPH to 120+ TPH, depending on the requirements of a project.

Asphalt Drum Mix Plant Manufacturer

Asphalt Drum Mix Plant Supplier

Vinayak Equipments is a capable Asphalt Drum Mix Plant Suppliers that offers end-to-end solutions, such as:

- Plant design & manufacturing

- Delivery and on-site construction.

- Operator training and commissioning.

- After-sales support and spare part services.

We have a solid supply chain that provides a good supply flow and reliable service during the project life cycle.

Why Choose Vinayak Equipments

Vinayak Equipment is a choice of investing in innovation, reliability, and long-term value.

Vinayak Equipments is a No.1 company that serves the asphalt drum and concrete plant industry, with a history of more than 10 years of serving its customers globally, installing 350+ successful plants. We have a powerful in-house research, development, and design team, providing efficient and sustainable innovative solutions to roads.

We export to over 35 countries, with each machine being of world standards at affordable prices, with a fast delivery service. With our committed after-sales service and easy access to spare parts, it promises the highest uptime and productivity – more than the customers expect.

Global Reach

Vinayak Equipments has built a good international base with installations in Africa, the Middle East, Asia, and South America. We are proud to be one of the most desired worldwide Asphalt Drum Mix Plant Exporters with stable quality, professional service, and delivery on time.

Our machines are also made to be efficient in various climatic conditions, such as humid tropics and arid deserts, to work smoothly with little or no downtime at all.

Our Commitment to Quality

All the machines in Vinayak Equipment are fabricated with accuracy and put under tight quality control measures. We have based our continuous improvement on customer feedback, which has assisted us in the development of industry-leading technology in the asphalt and concrete industry.

Our plants are eco-friendly and safe to the operator because we adhere to all the applicable environmental and safety requirements.