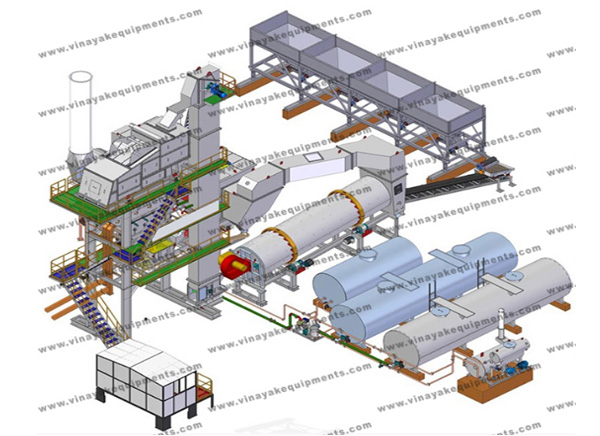

Asphalt Batch Mix Plant for Precise and High-Quality Asphalt Production

An Asphalt Batch Mix Plant is a plant that is capable of producing a perfectly blended asphalt mixture at a consistent quality that is required in the construction of a demanding road construction project. All batches are measured, mixed, and monitored with a high level of accuracy and guarantee high performance and long durability pavements. This batch-type hot Mix Plant is ideal for providing a contractor with control over the mix and ensuring efficiency, reliability, and flexibility for different asphalt recipes.

Engineered for Accuracy and Performance in Every Batch

The Asphalt Batch Mix Plant is manufactured using modern control technology and high-degree accuracy of the components, making sure that the mix is uniform, the temperature is optimal, and the bitumen coating is the same. It has a modular design that makes it easy to maintain and install with ease, and an efficient drying and mixing system that increases productivity without compromising quality, and is ideal for national highways, airports, and massive infrastructure projects.

Batch Type Hot Mix Plant for Modern Road Construction Needs

Asphalt Batch Mix Plant by Vinayak is a blend of intelligent automation and rugged engineering to suit the most demanding project requirements. It has a high-efficiency burner, a dust collection system, and a sophisticated control panel that reduces emissions and maximizes output. It is designed to meet the needs of contractors who are concerned with quality control, safety of operations, and sustainability of any road surface they construct.

Engineered for Accuracy and Performance in Every Batch

The Asphalt Batch Mix Plant is manufactured using modern control technology and high-degree accuracy of the components, making sure that the mix is uniform, the temperature is optimal, and the bitumen coating is the same. It has a modular design that makes it easy to maintain and install with ease, and an efficient drying and mixing system that increases productivity without compromising quality, and is ideal for national highways, airports, and massive infrastructure projects.

Batch Type Hot Mix Plant for Modern Road Construction Needs

Asphalt Batch Mix Plant by Vinayak is a blend of intelligent automation and rugged engineering to suit the most demanding project requirements. It has a high-efficiency burner, a dust collection system, and a sophisticated control panel that reduces emissions and maximizes output. It is designed to meet the needs of contractors who are concerned with quality control, safety of operations, and sustainability of any road surface they construct.

Applications of Asphalt Batch Mix Plant

Ideal for national and state highways

Suitable for urban and rural roadways

Great for heavy-duty asphalt resurfacing

Perfect for airport and runway paving

Useful for industrial estate roads

Reliable for multi-layer road structures

Designed for export and global projects

Excellent for long-term maintenance jobs

Key Features of Asphalt Batch Mix Plant

Precision batch mixing technology

Fully automatic PLC control system

Energy-efficient heating and drying

Modular design for easy installation

Efficient dust collection mechanism

Consistent temperature and mix quality

Multiple asphalt mix recipe options

Rugged, long-lasting construction design

Technical Specifications of Asphalt Batch Mix Plant

| Specification | Description |

|---|---|

| Capacity | 80 – 240 TPH |

| Mixing Type | Batch Type Mixing |

| Fuel Type | Diesel / LDO / FO / Gas |

| Dryer Drum | Counter Flow Type |

| Bitumen Tank | 25,000 – 40,000 Litres |

| Control System | Fully Automatic with SCADA |

| Dust Control | Multi-Stage Bag Filter Unit |

| Power Requirement | 60 – 125 HP |